In electronics, developers frequently encounter two fundamental components: the Printed Circuit Board (PCB) and the Development Board. While both involve circuit boards, they serve very different purposes. A PCB provides the structural and electrical foundation for components in a finished device. A Development Board, by contrast, is a ready-to-use platform for Prototyping, experimentation, and learning. Understanding their differences helps engineers, students, and hobbyists make efficient design and production decisions.

The Role of a PCB

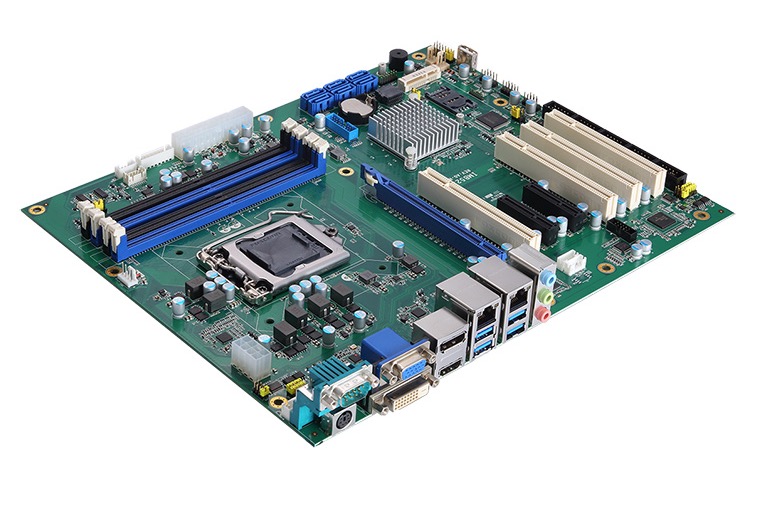

A PCB mechanically supports and electrically connects electronic components through copper traces and pads. Manufacturers use PCBs in devices ranging from smartphones to industrial controllers. Standard PCBs can have one to sixteen layers, depending on complexity. High-volume production can reduce unit cost to as low as $0.10 per board, but tooling and setup costs are higher. PCBs provide precise trace routing, optimized power distribution, and signal integrity, which make them ideal for commercial products. They are also critical for meeting regulatory compliance and quality standards.

What a Development Board Offers

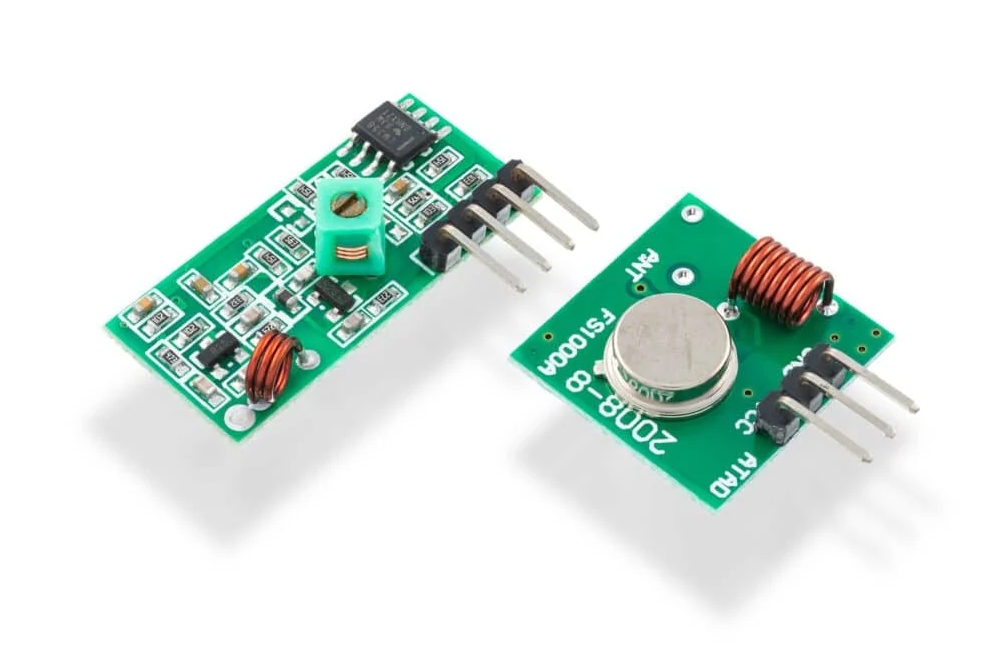

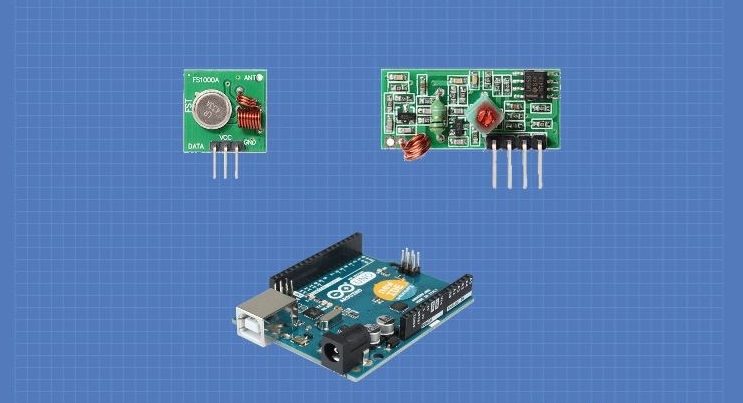

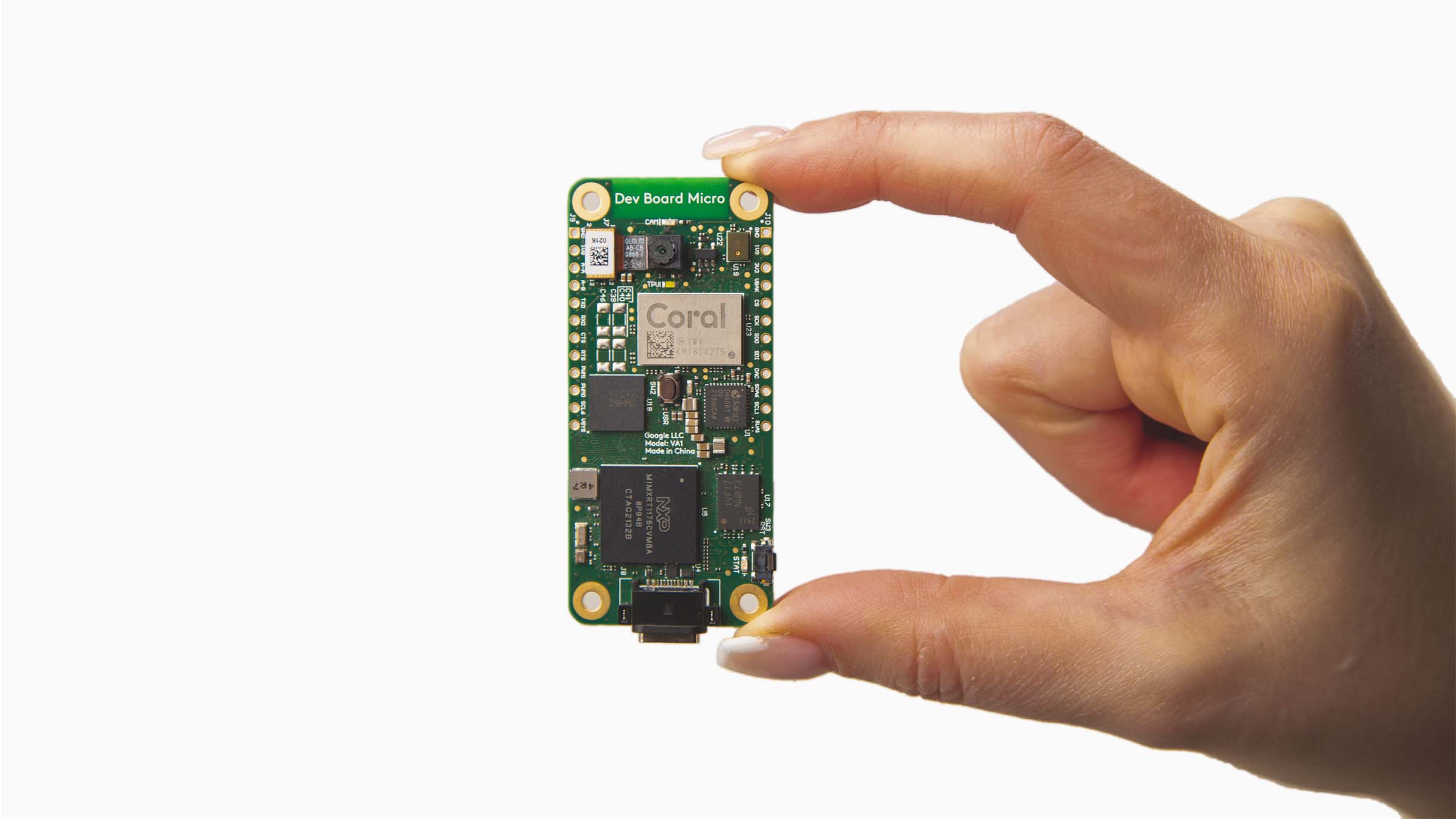

A Dev Board builds on the PCB concept by including pre-soldered microcontrollers, connectors, LEDs, and buttons. It allows engineers to program, test, and iterate quickly without manufacturing a custom PCB. Development Boards accelerate Prototyping and reduce the learning curve for beginners. For example, the Arduino Uno includes an ATmega328 microcontroller with built-in input/output interfaces. Users can create simple robotics, IoT devices, or automated home systems within hours. Raspberry Pi boards provide a Linux environment for more complex applications like AI edge computing. These platforms offer both versatility and educational value.

Comparing Key Features

Understanding the distinctions between a PCB and a Development Board ensures proper use:

| Feature | PCB | Development Board |

|---|---|---|

| Purpose | Final product manufacturing | Prototyping and testing |

| Components | Bare traces, pads, and vias | Microcontrollers, I/O, LEDs, buttons |

| Customization | Fully tailored for the product | Limited to pre-designed layout |

| Learning Curve | Requires soldering and circuit knowledge | Beginner-friendly with tutorials |

| Cost | Low in bulk, high setup cost | Higher per unit but reusable |

PCBs are optimized for durability and performance. Development Boards prioritize flexibility, speed, and ease of use for testing and learning.

When to Use a Development Board

Development Boards excel in early-stage projects. They allow rapid testing of circuit designs, software validation, and hardware exploration. Universities often use Arduino or STM32 Nucleo boards in electronics labs to teach programming and sensor interfacing. Startups rely on these boards for IoT prototypes, robotics, and automation devices. By experimenting on a Development Board first, teams identify design flaws without costly manufacturing errors. According to a 2022 survey, over 70% of maker projects begin on Development Boards before switching to custom PCBs.

Transitioning to a Custom PCB

Once a project matures, moving to a custom PCB ensures performance, reliability, and scalability. Custom PCBs reduce wiring mistakes, improve signal quality, and allow compact designs. A robotics startup, for instance, replaced breadboard prototypes with custom PCBs, cutting assembly time by 30% and improving field reliability. Multilayer PCBs support high-frequency signals, controlled impedance, and complex routing, which are critical for commercial electronics. Custom PCBs also comply with industry standards such as IPC-2221 and RoHS, ensuring quality and environmental safety.

Real-World Examples

Development Boards serve as the foundation for numerous successful projects. Arduino boards power DIY robots, sensor networks, and educational kits. Raspberry Pi boards enable smart displays, media servers, and IoT gateways. STM32 Nucleo boards support industrial-grade applications like automation and monitoring. One university team used Arduino boards to prototype a greenhouse automation system, testing sensors and motor controls. After successful Prototyping, they transitioned to a custom PCB to deploy a compact, reliable system capable of monitoring temperature, humidity, and irrigation schedules.

Unlock the Hidden Potential of Your Development Board

Development Boards are more than just prototyping tools—they are gateways to innovation. Beyond basic circuits, they can integrate multiple sensors, connect to cloud platforms, and even support AI-driven applications. For example, an Arduino or STM32 board can collect environmental data, send it to a cloud database, and trigger automated actions in smart homes or industrial systems. Raspberry Pi boards allow developers to experiment with edge computing, machine learning, and multimedia projects without custom PCBs. By exploring these capabilities, engineers and hobbyists can unlock new applications, streamline workflows, and turn prototypes into impactful, real-world solutions.