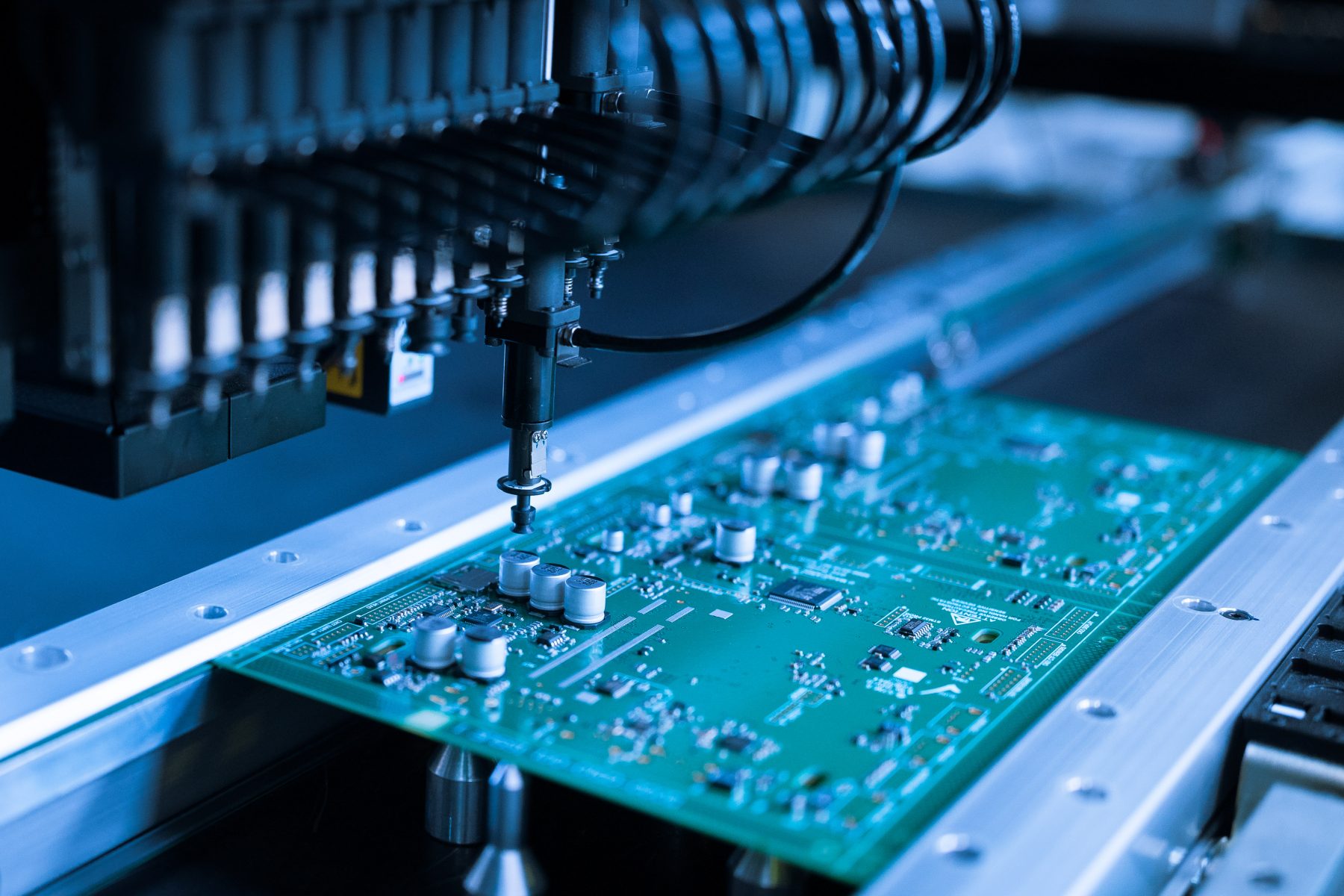

In the electronics manufacturing industry, efficiency is a key factor determining competitiveness and profitability. PCBA turnkey solution offers an integrated approach that combines component sourcing, assembly, and functional testing. Manufacturers no longer need to coordinate multiple suppliers and deal with communication barriers; they can manage the entire process with a single supplier. This model simplifies the production process, minimizes hidden costs, and shortens delivery cycles.

Simplifying the Supply Chain

Managing several suppliers often means dealing with inconsistent delivery times, varied documentation, and unpredictable quality. Each stage adds potential delays and increases management costs. A PCBA turnkey provider consolidates these steps, sourcing all electronic components from verified distributors while maintaining strict quality standards. This unified control eliminates bottlenecks that typically occur when one vendor fails to deliver on time. The result is a predictable and efficient workflow, along with a smoother overall production experience.

For instance, when a telecom manufacturer switched to a turnkey partner, its procurement cycle shortened by nearly 30%. That improvement allowed earlier prototype testing, quicker design iterations, and faster market entry.

Reducing Procurement and Administrative Costs

Traditional PCBA projects often require handling multiple invoices, shipping costs, and separate communication channels. By integrating sourcing, fabrication, and assembly, a turnkey model drastically reduces administrative effort and financial overhead. The client submits one purchase order and receives a fully assembled, tested board in return.

This streamlined process eliminates redundant expenses associated with logistics coordination, customs clearance, and document verification. Many small- and medium-sized manufacturers report overall cost reductions between 10% and 20% after transitioning to a turnkey model—without compromising consistency, yield, or long-term reliability.

Minimizing Production Errors Through Centralized Control

Quality control becomes far more reliable when all stages of production occur within a single facility and under a unified management system. The turnkey provider tracks every component, assembly step, and test result, ensuring that any deviation is identified early. Immediate corrections prevent rework costs, material waste, and downtime.

A case from an industrial automation firm illustrates this clearly: after adopting a PCBA turnkey solution, their defect rate dropped from 3.2% to 0.8% within six months. This improvement saved thousands of dollars in warranty costs and significantly boosted brand credibility among clients.

Faster Prototyping and Shorter Lead Time

Speed to market is everything in sectors like IoT, EVs, and consumer electronics. A turnkey partner already has the infrastructure and skilled labor to move from prototype to mass production quickly. Component sourcing, SMT assembly, and testing co-occur, rather than sequentially, saving valuable time.

Through established supplier networks, PCBA turnkey providers can secure parts more quickly, even amid global shortages or logistical disruptions. For startups or design houses, this can mean cutting development cycles from three months to just four weeks—a game changer for product competitiveness and investor confidence.

Leveraging Engineering Expertise and DFM Optimization

Beyond manufacturing, many turnkey providers also offer design-for-manufacturing (DFM) services that further enhance cost efficiency. Engineers review PCB layouts to detect spacing, routing, or component placement issues that may affect assembly yield. Early feedback reduces redesign cycles, minimizes material waste, and ensures long-term stability.

This technical collaboration is especially valuable for companies lacking a dedicated hardware engineering team. For instance, optimizing trace widths or reducing component density can save up to 15% in assembly time while improving overall heat dissipation—two factors that directly impact durability and performance.

Enhanced Traceability and Data Transparency

In regulated sectors such as automotive, aerospace, or medical electronics, traceability is not a luxury—it’s mandatory. Turnkey PCBA providers integrate advanced tracking systems that record every batch number, serial code, and inspection log. Clients receive complete documentation packages, which simplify audits, certifications, and compliance reporting.

This visibility also enhances accountability and post-sale support. If a component issue arises, the manufacturer can quickly identify affected units and prevent costly recalls. Transparency like this strengthens trust and creates long-term, collaborative relationships between OEMs and their manufacturing partners.

The Future of Electronics Manufacturing with PCBA Turnkey Solution

PCBA turnkey solutions enable manufacturers to focus on innovation, product design, and marketing, while delegating complex production logistics to experts. By eliminating redundancy, ensuring consistent quality, and accelerating every stage of the production cycle, this solution significantly improves cost-effectiveness and delivery speed. Companies adopting the turnkey model not only reduce costs but also effectively address challenges such as supply chain disruptions and labor shortages.