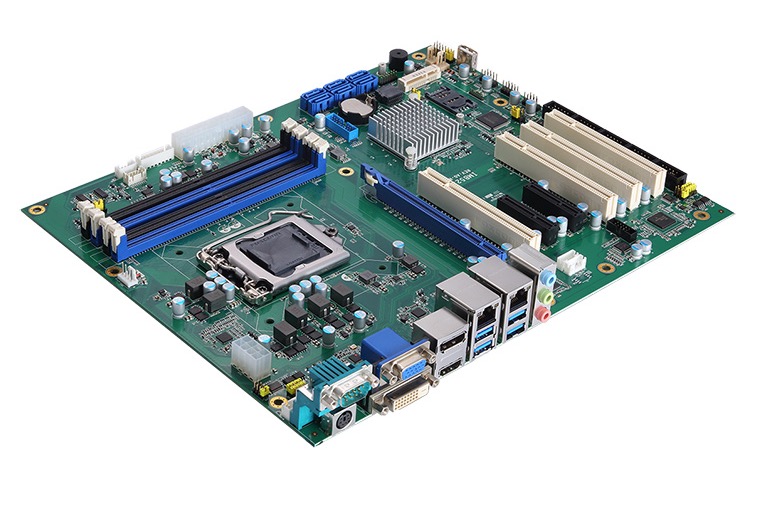

High-performance systems generate significant heat during continuous operation. Processors, GPUs, PMICs, and high-density I/O clusters all contribute to thermal stress. Industrial environments amplify these challenges. Many machines run 24/7, often inside sealed enclosures with minimal airflow. Heat buildup reduces component reliability and shortens system lifespan. The Industrial Motherboard must therefore manage thermal loads efficiently. Engineers should analyze chip-level heat output, airflow paths, and enclosure restrictions early in the design phase.

Evaluating Heat Sources in Complex Systems

Thermal design begins by identifying all primary heat sources. CPUs can reach 65–95W TDP in modern embedded systems. Edge AI accelerators can add another 30W or more. VRMs and SSDs also produce concentrated heat spikes. These values are documented by Intel, AMD, and major component vendors, so engineers should use validated data. Accurate mapping helps determine whether passive cooling is sufficient or if active cooling is required. This analysis also guides PCB layer structure and component spacing.

Airflow Planning for Enclosed Installations

Airflow is the most critical factor in thermal management. Industrial cabinets often restrict open airflow and depend on controlled internal circulation. Designers should visualize the airflow path and ensure key components face incoming air. Straight paths reduce turbulence and improve cooling performance. Fans should push cool air into hot zones rather than create dead-air pockets. Many factories rely on positive-pressure cabinets to prevent dust intake, which influences fan selection and vent placement. Effective airflow planning increases system stability and reduces thermal throttling.

Heat Sink and Material Selection

Heat sinks play a central role in thermal control. Aluminum remains common due to its balance of weight, cost, and thermal conductivity. Copper handles heat more effectively, so some vendors combine both materials. Engineers should also consider fin density, surface area, and mounting pressure. A poorly seated heat sink negates system performance benefits. For GPU or AI accelerators, custom extruded heat sinks often deliver better coverage. Thermal interface materials such as pads or paste must support long-term operation. Industrial settings demand materials that resist drying and vibration.

Thermal Solutions for High-Density Components

Modern Industrial Motherboard designs support more compact layouts. This trend increases thermal density. High-speed RAM, PCIe modules, and M.2 SSDs all cluster around power and data buses. Engineers should use heat spreaders and thermal shields to distribute heat away from tight zones. M.2 SSDs benefit from small heat sinks, which significantly reduce temperature. VRMs often require dedicated heat sinks to maintain a stable voltage supply. Component separation by only a few millimeters can reduce heat concentration and extend system life. Effective micro-level thermal management prevents failure under peak load.

Cooling Strategies for Harsh Industrial Environments

Harsh environments demand more robust cooling strategies. High humidity, dust, and vibration influence material selection and cooling method. Fanless cooling is standard in chemical plants or food processing lines. These systems rely on conduction instead of airflow. Engineers use thick heat pipes or vapor chambers to transfer heat toward external chassis surfaces. Laboratory tests show that vapor chambers perform better under fluctuating thermal loads. In dusty workshops, filtered airflow systems are safer than open-vented designs. Cooling strategies must reflect environmental risks, not only performance needs.

Validation and Continuous Thermal Testing

Thermal design requires validated testing. Engineers should run stress scenarios using real-world workloads. For example, Cinebench, FurMark, or embedded AI benchmarks can simulate peak heat loads. Thermal cameras and sensors help capture hotspots and airflow anomalies. Most manufacturers follow JEDEC and IPC standards for thermal evaluation. Extended burn-in tests verify long-term stability. This step is essential for any Industrial Motherboard intended for automation, robotics, or field systems. Real testing ensures that theoretical cooling strategies perform correctly in rugged conditions.

Ensuring Long-Term Stability for High-Performance Industrial Motherboard

Effective thermal design is critical for any high-performance Industrial Motherboards, especially in continuous-operating environments and harsh conditions. Engineers should combine component-level heat analysis, optimized airflow, suitable materials, and strict thermal testing. These principles help ensure reliable system operation and longer product lifespan. When applied consistently, they reduce downtime and create predictable performance across a wide range of industrial applications.