Radio Frequency Identification (RFID) technology has become essential in industrial automation, logistics, healthcare, and retail. Yet, one question often arises: should you choose a UHF or HF RFID Module? Both technologies serve similar purposes but operate under very different conditions. Understanding these differences enables engineers, system designers, and procurement managers to make informed choices regarding accuracy, scalability, and cost efficiency in IoT deployments.

Frequency and Communication Range

UHF (Ultra High Frequency) RFID works between 860 and 960 MHz, offering read ranges that can extend up to 12 meters in open environments. It enables non-line-of-sight communication, which is ideal for fast-moving inventory or large warehouses. HF (High Frequency) RFID, operating at 13.56 MHz, offers shorter read ranges—typically from 10 cm to 1 meter—but provides more stable performance near metal surfaces or in the presence of liquids. This difference in signal behavior is crucial when designing applications that rely on consistent tag detection in variable environments.

Data Speed and Throughput

Data transfer speed is another significant difference. UHF modules can process thousands of tag reads per second, making them suitable for mass item tracking and logistics automation. For example, major retail chains such as Walmart and Decathlon rely on UHF RFID systems to maintain real-time visibility of their stock levels. In contrast, HF modules are slower but offer highly reliable communication with minimal error rates, making them perfect for secure access cards, ticketing, and asset authentication.

Compatibility and Industry Standards

Both module types follow different global standards. HF modules usually comply with ISO/IEC 14443 or 15693, which are widely used in banking, transportation, and healthcare systems. UHF RFID modules, on the other hand, align with the EPC Gen2 (ISO/IEC 18000-6C) protocol, enabling global interoperability for supply chains. Understanding these standards is essential for developers who need compliance in regulated environments or across multiple countries.

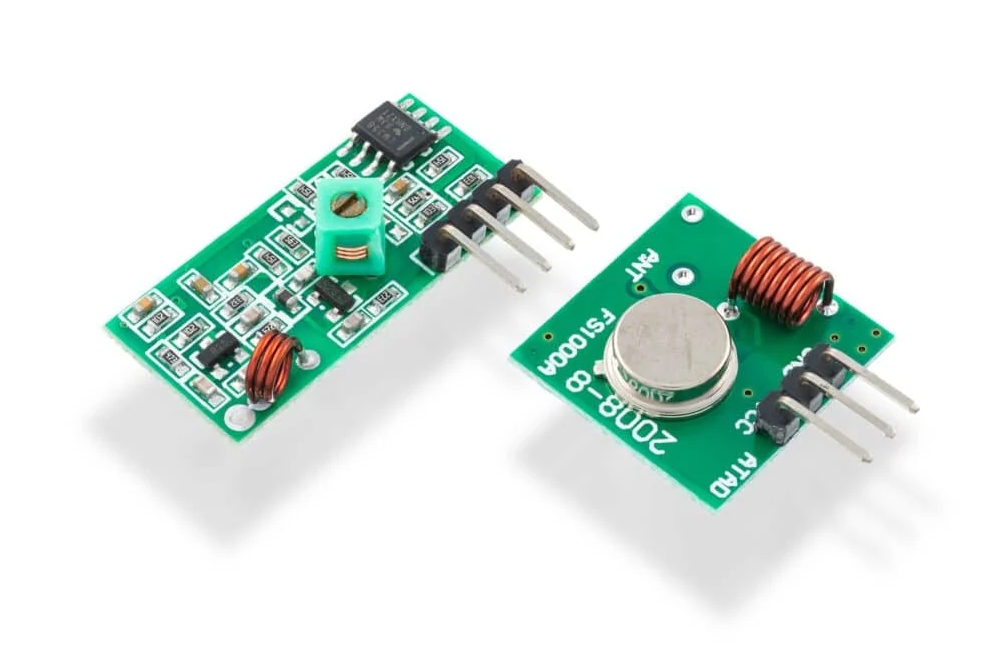

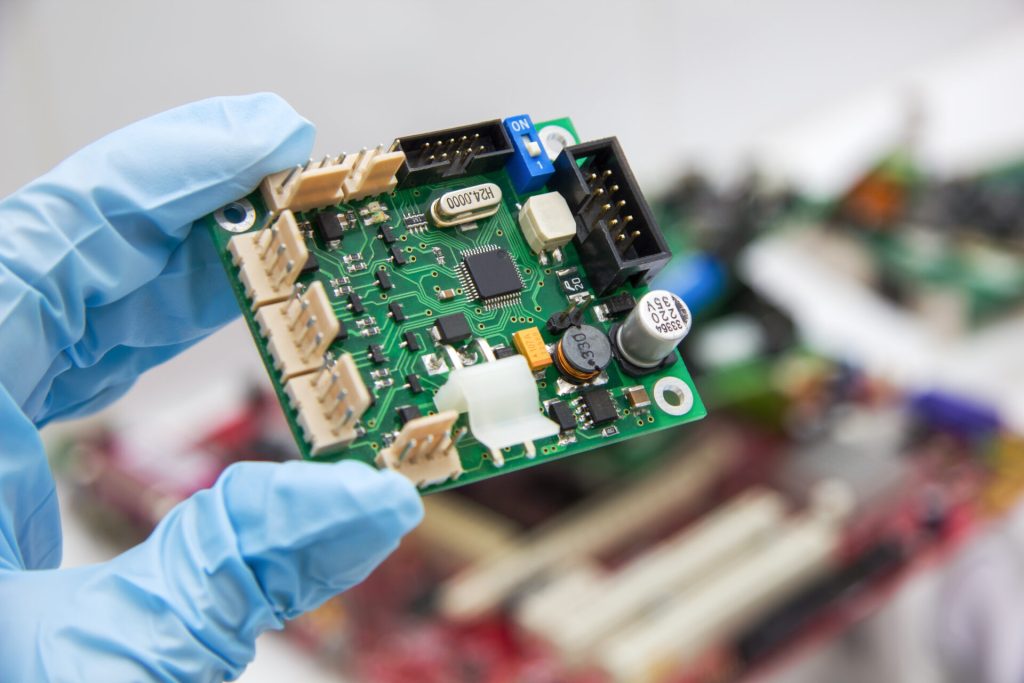

Integration and Hardware Design

The integration process also varies significantly. A UHF RFID Module often requires external antennas with impedance matching to maximize range and minimize signal reflection. This setup offers flexibility but requires precise tuning to achieve optimal results. HF modules are generally easier to integrate, as they often come with built-in antennas or coil designs that fit compact devices, such as smart cards, wristbands, and handheld readers. For smaller products or consumer-facing devices, HF’s compact form factor is a key advantage.

Cost, Power, and Scalability

Cost and scalability are decisive factors for any deployment. UHF RFID tags can cost less than $0.05 per unit, making them highly scalable for inventory management and retail applications. HF RFID tags, while slightly more expensive, provide better data integrity and encryption support. Power consumption also differs—UHF readers generally require more power to maintain long-range communication, while HF systems can operate efficiently in low-power or battery-driven setups. For large-scale industrial projects, these factors influence the total cost of ownership and long-term ROI.

Security and Interference

Security is one area where HF modules have a clear edge. HF communication supports encryption standards, such as AES, and mutual authentication, ensuring secure data transfer for applications like payment cards and electronic passports. UHF modules are more susceptible to interference from environmental noise and reflection; however, recent firmware innovations and antenna diversity techniques have improved their accuracy by up to 20% in real-world conditions. When security and data privacy are critical, HF remains the more trusted option.

Case Studies and Performance Insights

Real-world applications show how context defines performance. In 2023, a European logistics provider utilized UHF RFID modules to track over 150,000 pallets weekly, achieving a read accuracy of 97.8% even in high-speed conveyor systems. Meanwhile, a large U.S. hospital chain implemented HF RFID for tracking surgical instruments, resulting in a 40% reduction in lost equipment incidents and an improvement in sterilization workflow. These examples demonstrate that the best choice depends entirely on the operating environment and project goals.

| Category | UHF RFID Module | HF RFID Module |

|---|---|---|

| Operating Frequency | 860–960 MHz | 13.56 MHz |

| Typical Read Range | Up to 12 meters | 10 cm to 1 meter |

| Data Transfer Speed | High – thousands of tags per second | Moderate – stable, low error rate |

| Common Standards | EPC Gen2 (ISO/IEC 18000-6C) | ISO/IEC 14443, ISO/IEC 15693 |

| Best Use Cases | Inventory tracking, warehouse automation, logistics | Access control, payments, healthcare, ticketing |

| Tag Cost | As low as $0.05 per tag | Typically $0.10–$0.30 per tag |

| Antenna Requirement | External antenna with impedance tuning | Often integrated or coil-based antenna |

| Performance Near Metal/Liquid | Reduced signal stability | More stable near metal or liquids |

| Security Features | Basic data protection, less encryption | Supports AES encryption and mutual authentication |

| Power Consumption | Higher – needs more energy for long range | Lower – suitable for low-power systems |

| Read Accuracy (Typical) | 95–98% depending on the environment | 99%+ in controlled environments |

| Example Applications | Retail logistics, pallet tracking, supply chain monitoring | Smart cards, e-passports, and medical assets tracking |

Selecting the Right RFID Module for Long-Term Success

Choosing between UHF and HF RFID Module solutions is not about which is better—it’s about what fits your application. UHF excels in open environments that demand range and speed, while HF dominates in secure, close-range communication. Businesses should evaluate environmental conditions, read distance, security needs, and integration complexity before finalizing their choice. When selected correctly, the right RFID Module can enhance automation, traceability, and operational performance across industries—from logistics and healthcare to retail and manufacturing.