Embedded systems depend on accurate and timely data exchange. Sensors, controllers, and gateways must communicate without loss or distortion. Even minor transmission errors can trigger system faults. In industrial automation, a missed packet can halt production. In medical devices, data integrity directly affects safety. Engineers, therefore, treat communication reliability as a core design requirement. A Wireless Module often becomes the backbone of that communication layer. Its role extends beyond simple radio transmission. It manages signal stability, protocol handling, and error control. Reliable data flow starts with understanding how wireless links behave in real environments.

Core Architecture Behind Wireless Communication Reliability

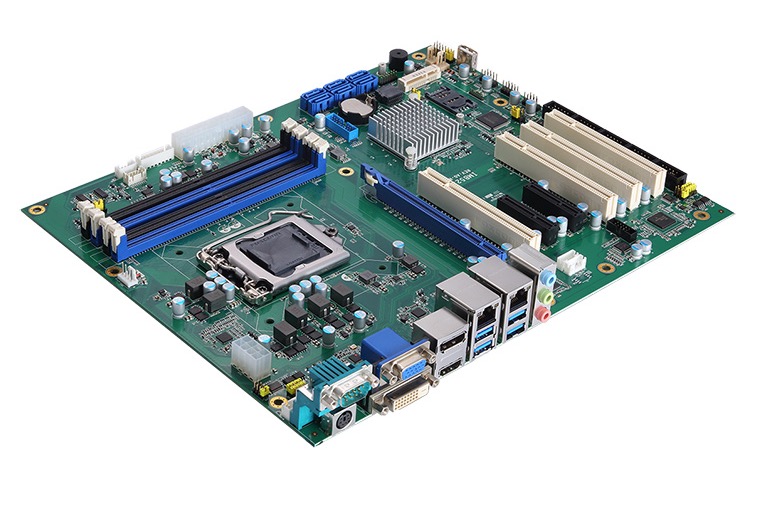

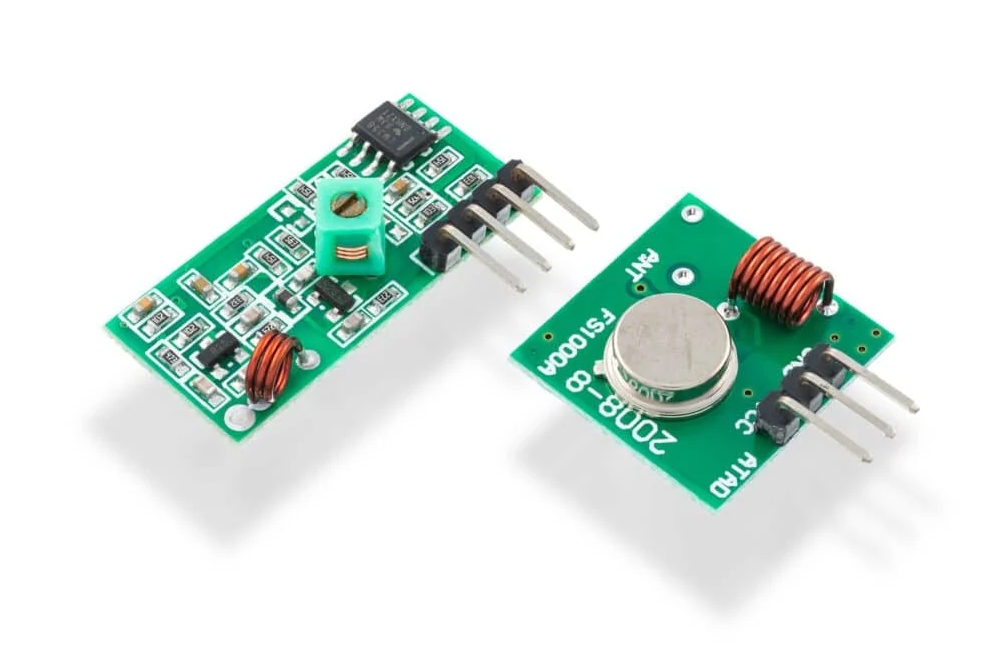

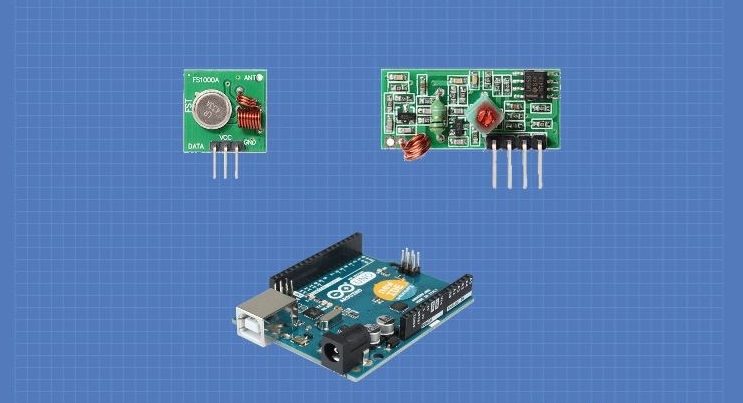

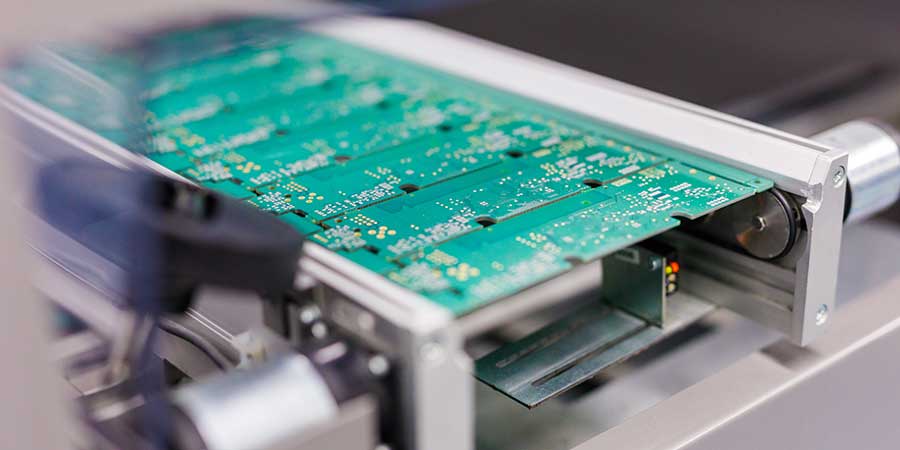

A modern wireless module integrates RF transceivers, baseband processing, and embedded firmware. This architecture reduces variability in signal handling. The RF front end manages modulation, filtering, and amplification. Baseband logic encodes data and applies error detection. Firmware controls timing, retries, and acknowledgments. These layers work together to stabilize communication. Designers gain predictable performance without building RF systems from scratch. This integration lowers development risk and improves consistency across devices. In embedded systems, such predictability simplifies validation and long-term maintenance.

Error Detection and Correction Mechanisms

Reliable transmission depends on detecting and correcting errors early. Wireless links are subject to noise, interference, and fading. Modules address this through CRC checks, packet sequencing, and forward error correction. When a receiver detects corrupted data, it requests retransmission—some protocols repair errors without resending packets. IEEE 802.15.4 and Bluetooth Low Energy both use layered error control. These mechanisms significantly reduce effective packet loss. Field studies show packet success rates exceeding 99 percent in controlled deployments. Such performance makes wireless viable for mission-critical embedded applications.

Managing Interference and Environmental Noise

Embedded systems rarely operate in clean RF environments. Factories contain motors and inverters. Buildings contain WiFi and cellular signals. Wireless modules mitigate interference using channel hopping and adaptive data rates. Spread-spectrum techniques distribute energy across frequencies. This approach reduces sensitivity to narrowband noise. Many modules also measure signal quality in real time. They automatically adjust transmission power and timing. These features help maintain stable links without manual tuning. Engineers benefit from resilience across changing environments.

Power Control and Timing Synchronization

Reliable transmission requires precise timing. It also requires controlled power usage. Excess power creates interference. Insufficient power causes packet loss. Wireless modules dynamically adjust output power based on link conditions. They also synchronize clocks between nodes. Accurate timing reduces collisions and retransmissions. In low-power embedded systems, this balance extends battery life. Zigbee and Sub-GHz systems demonstrate multi-year battery operation in field deployments. Such efficiency supports remote sensors and distributed controllers. Reliability and energy efficiency reinforce each other.

Protocol Stack Optimization for Embedded Systems

A Wireless Module often includes a certified protocol stack. This stack manages addressing, routing, and acknowledgments. Engineers avoid implementing complex protocols themselves. Pre-tested stacks reduce software defects. They also ensure standards compliance. Mesh routing in Zigbee networks provides alternate paths when nodes fail. Point-to-point Sub-GHz links simplify long-range communication. Each approach serves different reliability goals. Selecting the right stack improves system robustness. It also shortens development cycles and certification timelines.

Real-World Applications and Performance Evidence

Industrial monitoring systems provide strong evidence of wireless reliability. Smart meters transmit usage data daily with minimal failure rates. Many utilities report availability above 99.5 percent. Warehouse automation systems use wireless modules for mobile scanners and sensors. These systems operate continuously in noisy RF environments. Hospitals use embedded wireless links for patient monitoring. Regulatory standards require predictable performance. These deployments confirm that properly selected modules meet strict reliability requirements. They also show scalability across thousands of nodes.

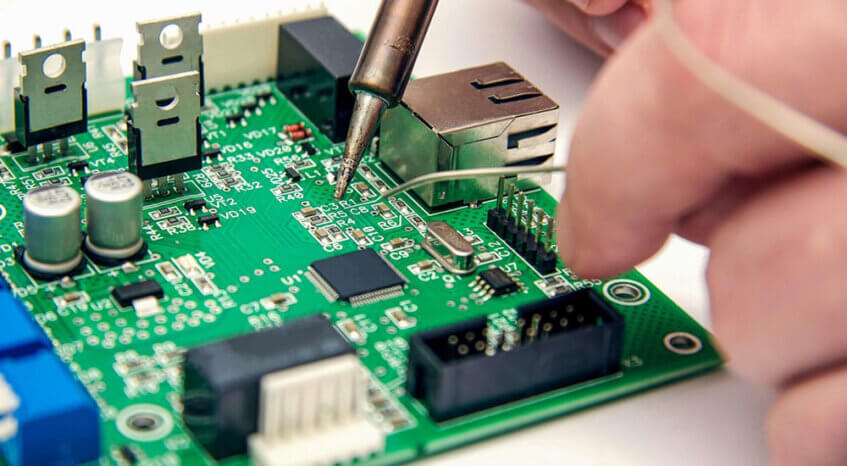

How a Wireless Module Supports Long-Term System Reliability

A Wireless Module does more than transmit data. It enforces consistency across hardware and software layers. Certified modules reduce regulatory risk. Extended lifecycle support ensures availability for industrial products. Vendors provide firmware updates to address security and performance issues. This support protects deployed systems for many years. Engineers who prioritize module quality reduce maintenance costs. They also improve system uptime. Reliable data transmission becomes a design outcome rather than a constant concern. Embedded systems achieve stability when the communication infrastructure remains dependable.